Other specialized high-performance adhesives

Category:

Home Products

Key Words:

Home Products

MESSAGE

Listen & Deliver Trusted Solutions.

- 产品描述

-

- Commodity name: Other specialized high-performance adhesives

High-performance adhesive is a specialized adhesive whose main materials include epoxy resin, polyurethane, acrylic resin, etc. It has the characteristics of high strength, high heat resistance, and corrosion resistance. It is widely used in automobile manufacturing, aerospace, construction, electronic products and other fields, and is one of the indispensable and important materials in modern production and manufacturing.

Product introduction

High-performance adhesive is a specialized adhesive whose main materials include epoxy resin, polyurethane, acrylic resin, etc. It has the characteristics of high strength, high heat resistance, and corrosion resistance. It is widely used in automobile manufacturing, aerospace, construction, electronic products and other fields, and is one of the indispensable and important materials in modern production and manufacturing.

The main function of high-performance adhesives is to firmly bond two or more objects together so that they are not easy to fall off or deform during use. It can replace traditional mechanical connection methods and improve the overall performance and stability of the product. In addition, high-performance adhesives are also waterproof, fireproof, and wear-resistant, which can increase the service life of the product.

The advantages of high-performance adhesives are mainly reflected in the following aspects:

1. High strength: High-performance adhesives have extremely high adhesion and tensile strength, and can withstand large tensile and shear forces to ensure the stability of the adhered objects.

2. Good heat resistance: High-performance adhesives can remain stable in high-temperature environments and are not easy to soften or fall off. They are suitable for bonding and fixing under high-temperature conditions.

3. Strong corrosion resistance: High-performance adhesives have excellent corrosion resistance and can resist erosion from external environments such as acids, alkalis, chemicals, etc., and maintain long-term and stable bonding effects.

4. Easy to use: High-performance adhesives usually use two-component or multi-component formulas. When using, you only need to mix them in a certain proportion and apply them to the surface to be bonded. The operation is simple and fast.

When using high-performance adhesives, you need to pay attention to the following points:

1. Read the product instructions carefully before use, and correctly mix and match the adhesive as required to avoid poor bonding results due to improper matching.

2. Keep the bonded surface clean and dry during use to avoid oil, dust, etc. from affecting the bonding effect.

3. After the bonding is completed, it must be well fixed and compacted to ensure that the adhesive can fully function and avoid cracking, falling off, etc. during use.

To sum up, high-performance adhesive is a specialized adhesive material with high strength, heat resistance, corrosion resistance and other characteristics, and is widely used in various industries. During use, correctly selecting the appropriate adhesive, following correct operating procedures, and paying attention to details can ensure the bonding effect and product quality.

Table parameters

No

Index

Product characteristics

Application area

Appearance

Solid/%

Viscosity

/mPa.s

25℃Ionic charge

JR-

3260Milky white liquid

50~

5550~

1500Negative ion

1. Soft and smooth textile

2. Good rebound performance

3. High fullness

4. Excellent low-temperature bending characteristics

5. Excellent resistance to yellowing1. Suitable for printing high-end clothing fabrics such as high elastic swimsuits, etc;

2. Dipped glove coating.JR-

6619Milky white liquid

43~

4720~

500Anionic non-ionic

1. Excellent bundling performance and good compatibility with various resins;

2. Excellent high temperature resistance, yellowing resistance, and water resistance;

3. Excellent compatibility with strong acid and alkali solutions, and electrolyte resistancevarious thermosetting and thermoplastic properties such as SMC, BMC, TP, etc

The main film-forming agent for fiberglass productsJR-

6630Milky white liquid

38~

4250~

500Anionic non-ionic

1. Excellent bundling performance and good compatibility with various resins;

2.Excellent resistance to high temperature and yellowing;

3. High modulus and strength;The main film-forming agent for fiberglass products

JR-

3210Milky white liquid

50±2

2000~

4000Negative ion

1. Resistance to yellowing;

2. Outstanding initial viscosity;

3. Excellent adhesive strength;

4. Excellent brushing performance;

5. Excellent heat and water resistance.1. Automotive interior adhesive

2. Flocking adhesive

3. Vacuum suction plastic adhesive

4. Heat transfer printing of carpets and other fabrics

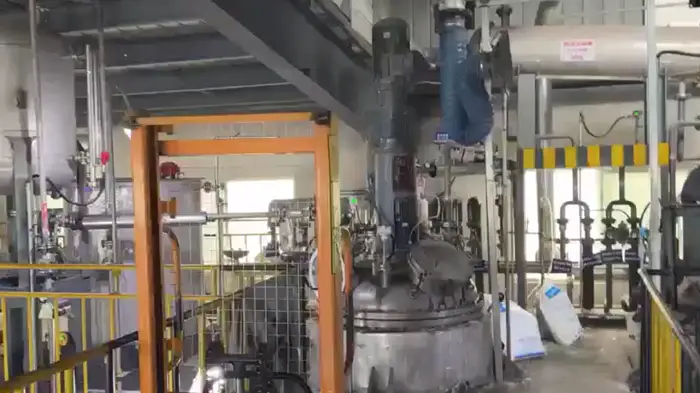

FACTORY

We have been deeply involved in the fields of UD fabric adhesives, textile adhesives, and reflective adhesives for many years, especially in the segmented fields of UD fabric adhesives, reflective fabric, reflective leather, cutting, and heat adhesives, with a market share of over 50%.

PACKING AND SHIPPING

Tai'an Juren New Materials Co., Ltd. was established in 2019 and is controlled by Beijing Juren Infinite Technology Co., Ltd. It mainly engages in the research and development, production, sales, and technical services of high-end industrial adhesives

VIDEO

Tai'an Juren New Materials Co., Ltd. was established in 2019 and is controlled by Beijing Juren Infinite Technology Co., Ltd. It mainly engages in the research and development, production, sales, and technical services of high-end industrial adhesives

Get a Quote or a Quick Support

Experienced project experts teams willprovide you with competitive quotes withthe best service and free samples

Contact us now

MESSAGE