Special high-performance adhesive for rope nets

Category:

Special high-performance adhesive for rope nets

Key Words:

Special high-performance adhesive for rope nets

MESSAGE

Listen & Deliver Trusted Solutions.

- 产品描述

-

- Commodity name: Special high-performance adhesive for rope nets

High-performance adhesive for rope nets is a powerful adhesive specially used for bonding rope net materials. Its unique formula and performance make it play an important role in rope net manufacturing and repair. The adhesive is mainly made of polymer materials and has excellent bonding strength and weather resistance, ensuring that the rope net maintains a stable connection in various harsh environments.

Product introduction

High-performance adhesive for rope nets is a powerful adhesive specially used for bonding rope net materials. Its unique formula and performance make it play an important role in rope net manufacturing and repair. The adhesive is mainly made of polymer materials and has excellent bonding strength and weather resistance, ensuring that the rope net maintains a stable connection in various harsh environments.

The main purpose of high-performance adhesives for rope nets is to bond ropes or meshes of different materials during the rope net manufacturing process to enhance its overall strength and durability. It is suitable for various rope net materials, including nylon, polyester, polyethylene, etc., and can be used to make various types of rope nets, such as climbing ropes, fishing nets, transportation nets, etc.

This adhesive offers the following key features and benefits:

1. High bonding strength: After bonding, the bonded parts of the rope net have extremely high strength and can withstand large pulling forces and impact forces, ensuring that the rope net will not fall off or break during use.

2. Weather resistance: The adhesive has been specially treated to have excellent weather resistance and heat resistance. It can maintain stable performance under various environmental conditions and is not easily affected by external factors such as sun, rain, and high temperature.

3. Rapid curing: The adhesive has a short curing time and can quickly reach maximum strength after bonding, saving manufacturing time and improving production efficiency.

4. Long-lasting bonding effect: The bonded rope net has a long-lasting bonding effect and is not prone to problems such as cracking and peeling, extending the service life of the rope net.

5. Safety and environmental protection: The adhesive is non-toxic, tasteless, contains no harmful substances, meets environmental protection requirements, and is safe and reliable to use.

When using special high-performance adhesives for rope nets, you need to pay attention to the following matters:

1. The bonding surface must be cleaned before use to ensure that there is no dirt or grease affecting the bonding effect.

2. When bonding, you must follow the operating methods in the instruction manual to ensure that the adhesive is evenly applied on the surface of the rope net to avoid bubbles or missed application.

3. It is necessary to wait for sufficient curing time after bonding to avoid loosening or falling off due to stress in advance.

4. When storing, it is necessary to avoid environments such as high temperature and humidity, and keep it dry and ventilated to avoid affecting the performance of the adhesive.

To sum up, high-performance adhesive for rope nets is a specialized bonding material that can effectively improve the strength and durability of rope nets and is widely used in the field of rope net manufacturing and maintenance. Its excellent functions and advantages ensure that the rope net can function stably and reliably in various harsh environments, making it an ideal choice for rope net manufacturers and users.

Table parameters

No

Index

Product characteristics

Application area

Main ingredient

Appearance

pH

Solid/%

Viscosity/mPa.s

25℃Ionic charge

JR-

30PU

Milky white liquid

5~8

30±1

1500~

8000Negative ion

1. Colloid hard and tough, with excellent wear resistance;

2. Excellent resistance to yellowing and water resistance;

3. Good compatibility with other non-ionic or anionic lotion resins;

4. Strong penetration, bright and full coloring color.Used for impregnating ropes and nets made of ultra-high molecular weight polyethylene fibers or polyamide fibers

JR-

55PU

Milky white liquid

5~8

30±1

1500~

8000Negative ion

1. Soft and resilient colloid, and the finished product has a soft touch;

2. Good compatibility with other non-ionic or anionic lotion resins;

3. Excellent resistance to yellowing and water resistance;

4. Strong penetration, bright and full color.Used for impregnating ropes and nets made of ultra-high molecular weight polyethylene fibers or polyamide fibers

JR-

40Polyolefin copolymer

Milky white liquid

4~8

40±1

1000~

8000Negative ion

1. Good compatibility with other non-ionic or anionic lotion resins and color pastes;

2. Colloidal hardness of the product is moderate, and it has excellent wear resistance;

3. Strong penetration and full coloring colorUsed for impregnating ropes and nets made of ultra-high molecular weight polyethylene fibers or polyamide fibers

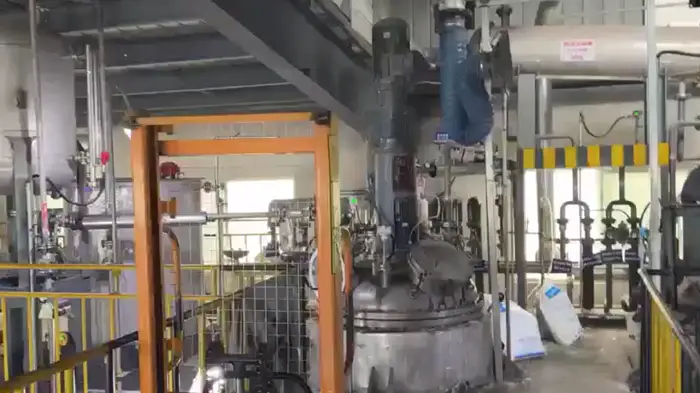

FACTORY

We have been deeply involved in the fields of UD fabric adhesives, textile adhesives, and reflective adhesives for many years, especially in the segmented fields of UD fabric adhesives, reflective fabric, reflective leather, cutting, and heat adhesives, with a market share of over 50%.

PACKING AND SHIPPING

Tai'an Juren New Materials Co., Ltd. was established in 2019 and is controlled by Beijing Juren Infinite Technology Co., Ltd. It mainly engages in the research and development, production, sales, and technical services of high-end industrial adhesives

VIDEO

Tai'an Juren New Materials Co., Ltd. was established in 2019 and is controlled by Beijing Juren Infinite Technology Co., Ltd. It mainly engages in the research and development, production, sales, and technical services of high-end industrial adhesives

Get a Quote or a Quick Support

Experienced project experts teams willprovide you with competitive quotes withthe best service and free samples

Contact us now

MESSAGE