Special high-performance adhesive for bulletoroofing

Category:

Special high-performance adhesive for bulletproofing

Key Words:

Special high-performance adhesive for bulletproofing

MESSAGE

Listen & Deliver Trusted Solutions.

- 产品描述

-

- Commodity name: Special high-performance adhesive for bulletoroofing

JR-0808 Special bulletproof high-performance adhesive is an adhesive specially used to fix bulletproof materials, which can effectively improve the impact resistance and protective performance of bulletproof materials. The adhesive is mainly made of high-strength polymer materials and has excellent bonding properties, high temperature resistance and corrosion resistance.

Product introduction

JR-0808 Special bulletproof high-performance adhesive is an adhesive specially used to fix bulletproof materials, which can effectively improve the impact resistance and protective performance of bulletproof materials. The adhesive is mainly made of high-strength polymer materials and has excellent bonding properties, high temperature resistance and corrosion resistance.

This adhesive is suitable for fixing and connecting various types of bulletproof materials, such as bulletproof panels, stab-resistant clothing, etc. It can form a strong adhesive layer on the surface of bulletproof materials, effectively improving the overall performance and impact resistance of bulletproof materials. At the same time, the adhesive can also reduce the weight of bulletproof materials and enhance their durability, making them more suitable for use in various extreme environments.

The advantages of this adhesive mainly include the following points: first, it has high bonding strength and can firmly bond various bulletproof materials to ensure that they will not fall off under high-intensity impact; second, it has good high-temperature resistance and can be used in high-temperature environments. The bonding performance will not be affected for a long time; thirdly, it has strong corrosion resistance and can resist the corrosion of various chemical substances, keeping the original performance of the bulletproof material unimpaired.

When using bulletproof special high-performance adhesives, you need to pay attention to the following points: First, make sure the surface to be bonded is clean and dry before use to ensure the bonding effect; second, the adhesive should be dried and cured at room temperature, and the curing time Generally 24 hours; again, avoid contact with skin and eyes when using, and rinse immediately with water if inadvertent contact; finally, store in a cool, dry place away from direct sunlight and humid environment.

In general, bulletproof high-performance adhesive is a very practical bonding material that can effectively improve the overall performance and impact resistance of bulletproof materials and ensure the safety of users in dangerous environments. As long as you pay attention to the precautions when using it, you can exert its effect and provide users with more reliable protection and safety.

Table parameters

Series

NO

Solids 160℃/30min

Four cups viscosity coating/s(25℃

Product characteristics

Application area

8

JR-0808

30

10-30

Slightly hard, easy to peel off, high composite temperature (110℃/5-6MPa)。

Chip UD; Film silk film silk pressing plate; UD series

JR-0810

30

10-30

Moderate hardness, easy to peel off, with the same performance as 350 glue, and higher cohesive strength than 350.

JR-0812

30

10-30

Soft, with lower composite temperature (90℃/5-6MPa)。

32

JR-3201

30

10-30

Shao D31-32, thermal activation temperature 65-70 ℃.

Film silk silk pressing plate;UD series

JR-3203

30

10-30

Shao D34-35, with a thermal activation temperature of 125-135 ℃, is less commonly used.

JR-3204

30

10-30

activation temperature is 55-65 ℃, and the performance is the same as U54.

JR-3205

40

10-30

Shao D39-40, activation temperature 80-90 ℃, performance like U8755.

Series

No

Solid 160℃/30min

Four cups viscosity coating/s(25℃

Product characteristics

Application area

42

JR-

420630

10-30

PE/Aramid soft UD universal, high composite temperature.

Customized products

JR-

425030

10-30

Film silk film silk hard board UD, colloid soft, which can increase the silk content without scattering.

JR-

425630

10-30

Universal soft UD, low composite temperature, high fastness, high online composite machine speed.

22

JR-

220435

10-30

Rubber water-based lotion, large molecular weight, soft, elasticity, high composite temperature.

JR-

220930

10-30

Waterborne acrylic lotion, easy to be compounded, no loose silk.

16

JR-

1601Thickness between 2.5-3.5g/m2, thermal activation temperature is around 130 ℃.

JR-1606

Thickness 5-6g/m2, activation temperature 80-90 ℃, product pilot stage.

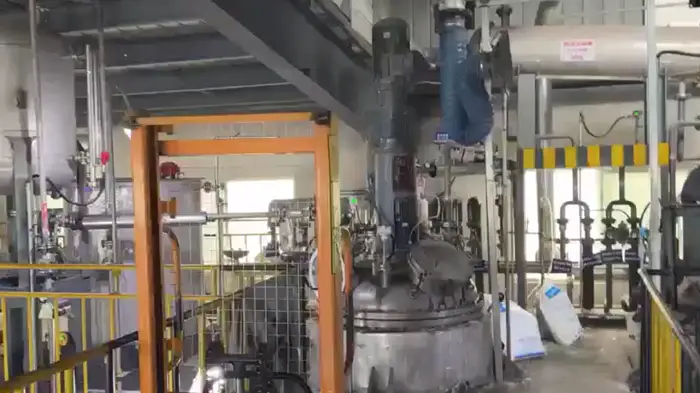

FACTORY

We have been deeply involved in the fields of UD fabric adhesives, textile adhesives, and reflective adhesives for many years, especially in the segmented fields of UD fabric adhesives, reflective fabric, reflective leather, cutting, and heat adhesives, with a market share of over 50%.

PACKING AND SHIPPING

Tai'an Juren New Materials Co., Ltd. was established in 2019 and is controlled by Beijing Juren Infinite Technology Co., Ltd. It mainly engages in the research and development, production, sales, and technical services of high-end industrial adhesives

VIDEO

Tai'an Juren New Materials Co., Ltd. was established in 2019 and is controlled by Beijing Juren Infinite Technology Co., Ltd. It mainly engages in the research and development, production, sales, and technical services of high-end industrial adhesives

Get a Quote or a Quick Support

Experienced project experts teams willprovide you with competitive quotes withthe best service and free samples

Contact us now

MESSAGE